Our Strategic use of 3D Modeling & Printing Streamlines the Idea-to-Implementation Process

At Torque & Assembly Solutions, we utilize 3D modeling and printing to assist in the design and manufacture of our custom products, providing many advantages to our partners:

Reduced Costs

By identifying design flaws and optimizing production processes before physical prototyping, 3D models and prints can significantly reduce material waste and manufacturing costs.

Improved Efficiency

The ability to quickly iterate on designs and simulate performance enables faster product development cycles.

Enhanced Collaboration

3D models and prints facilitate better communication and collaboration among engineers, designers, and other stakeholders.

Increased Accuracy & Precision

3D models and prints enable highly detailed and accurate representations of products, thereby minimizing manufacturing errors.

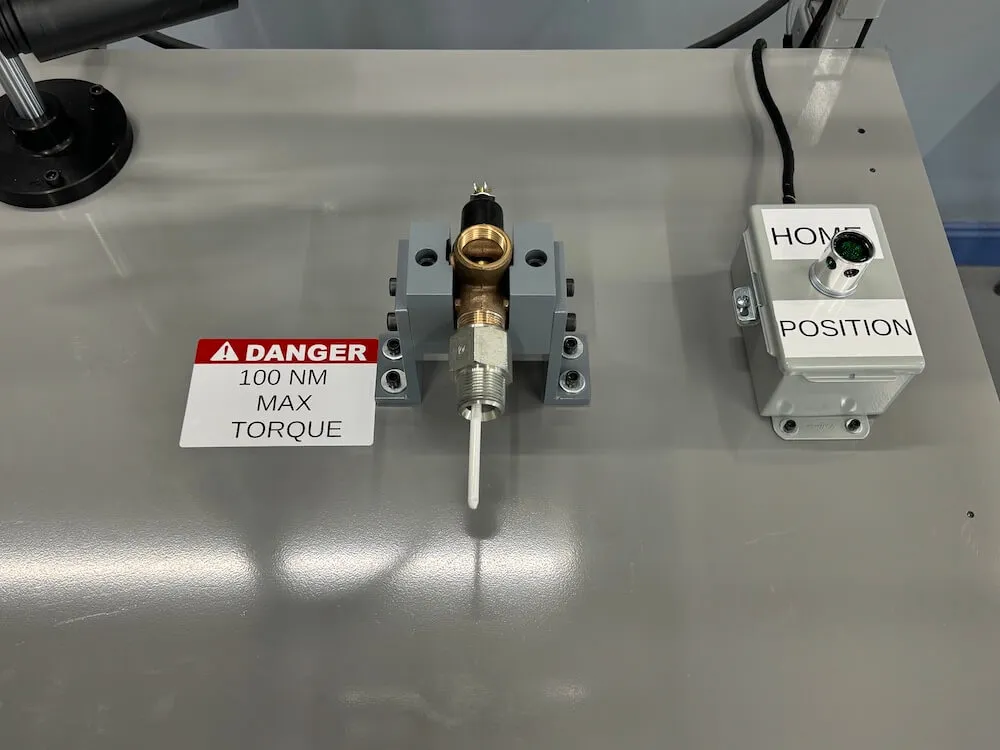

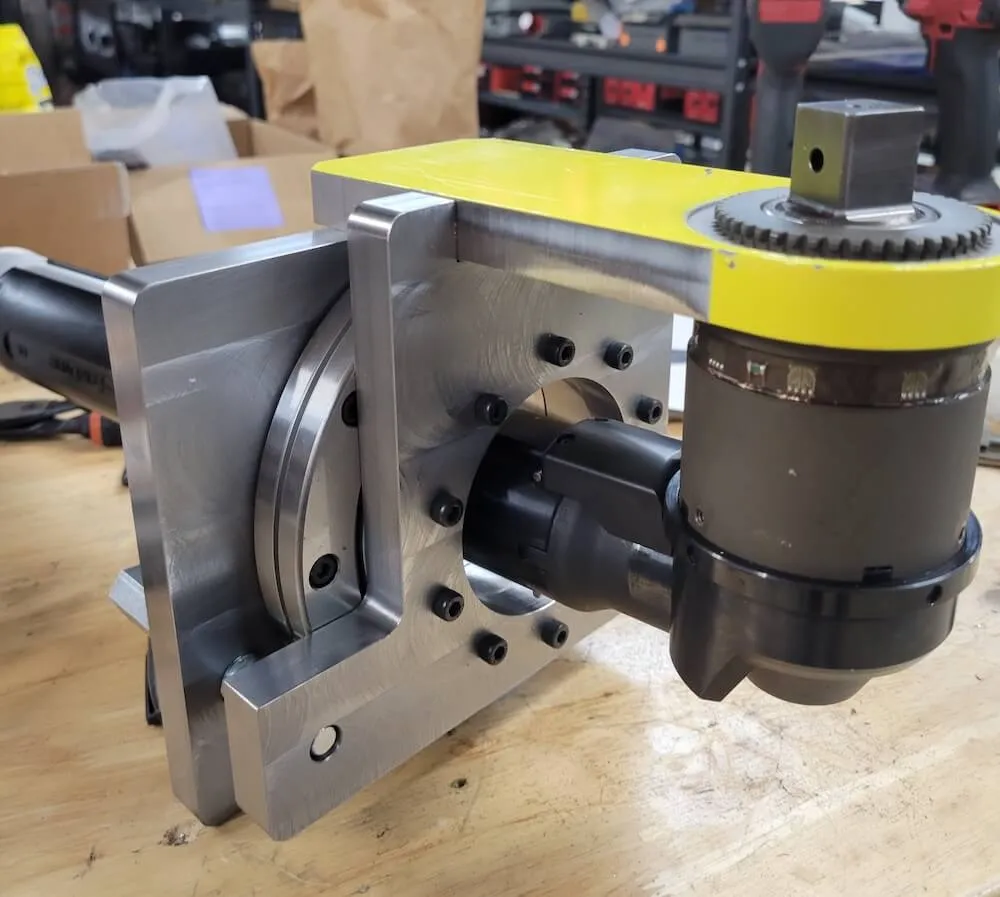

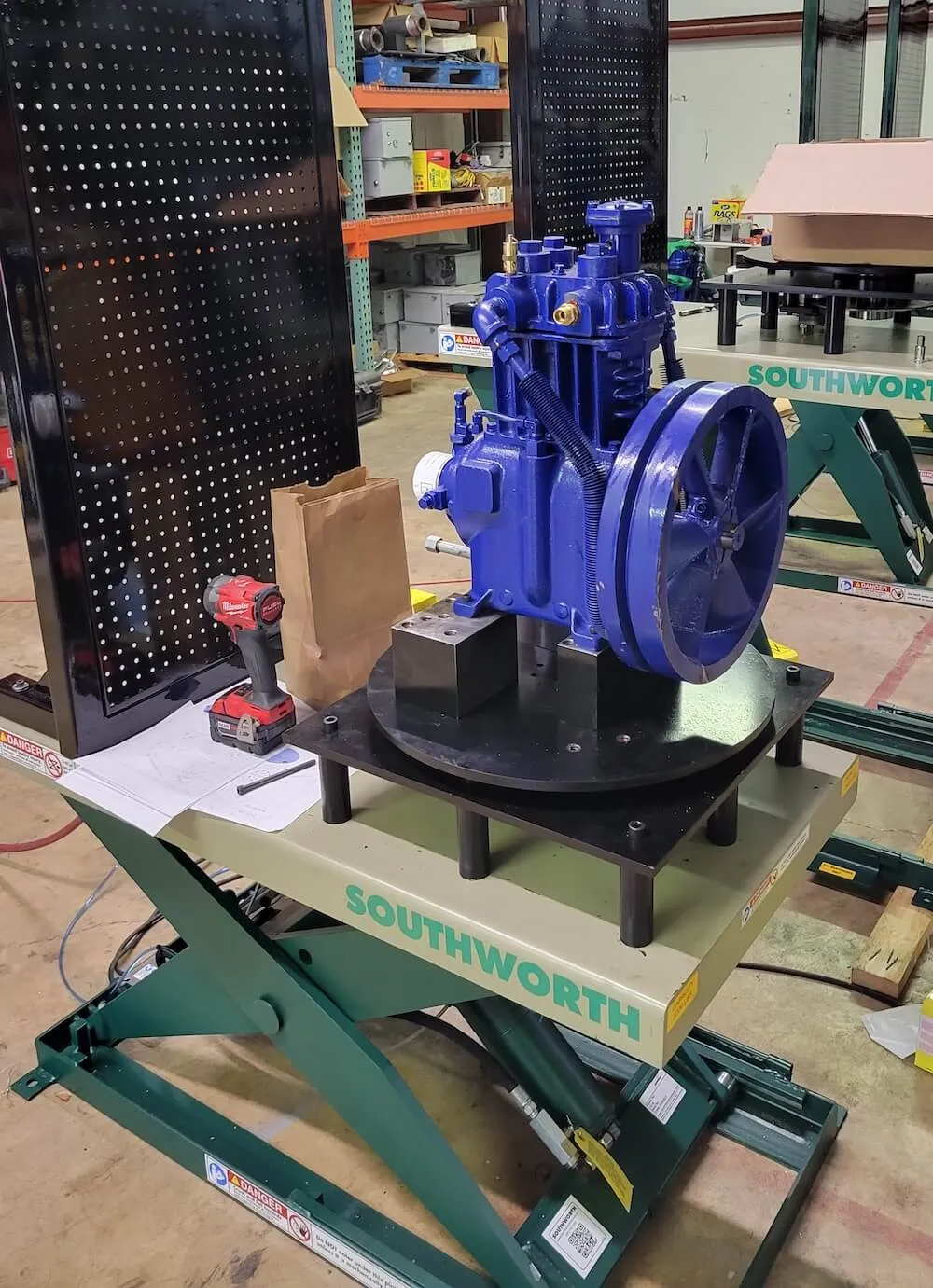

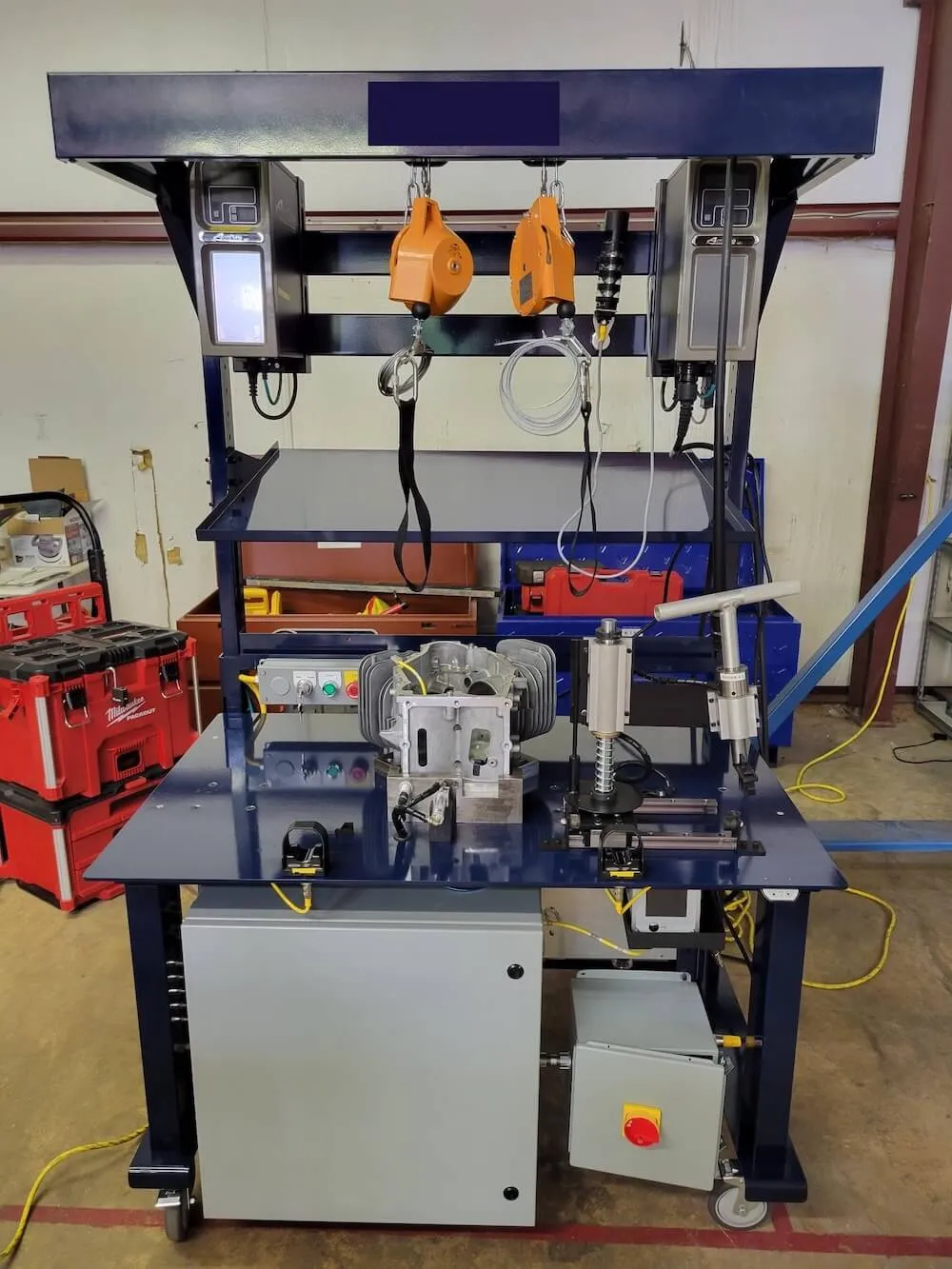

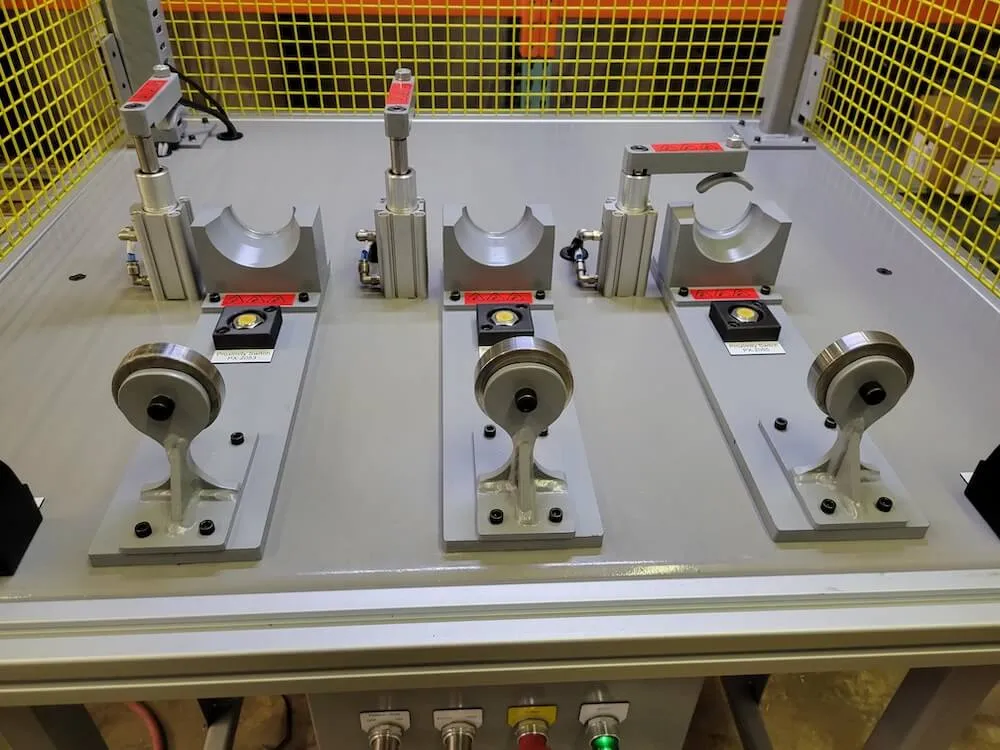

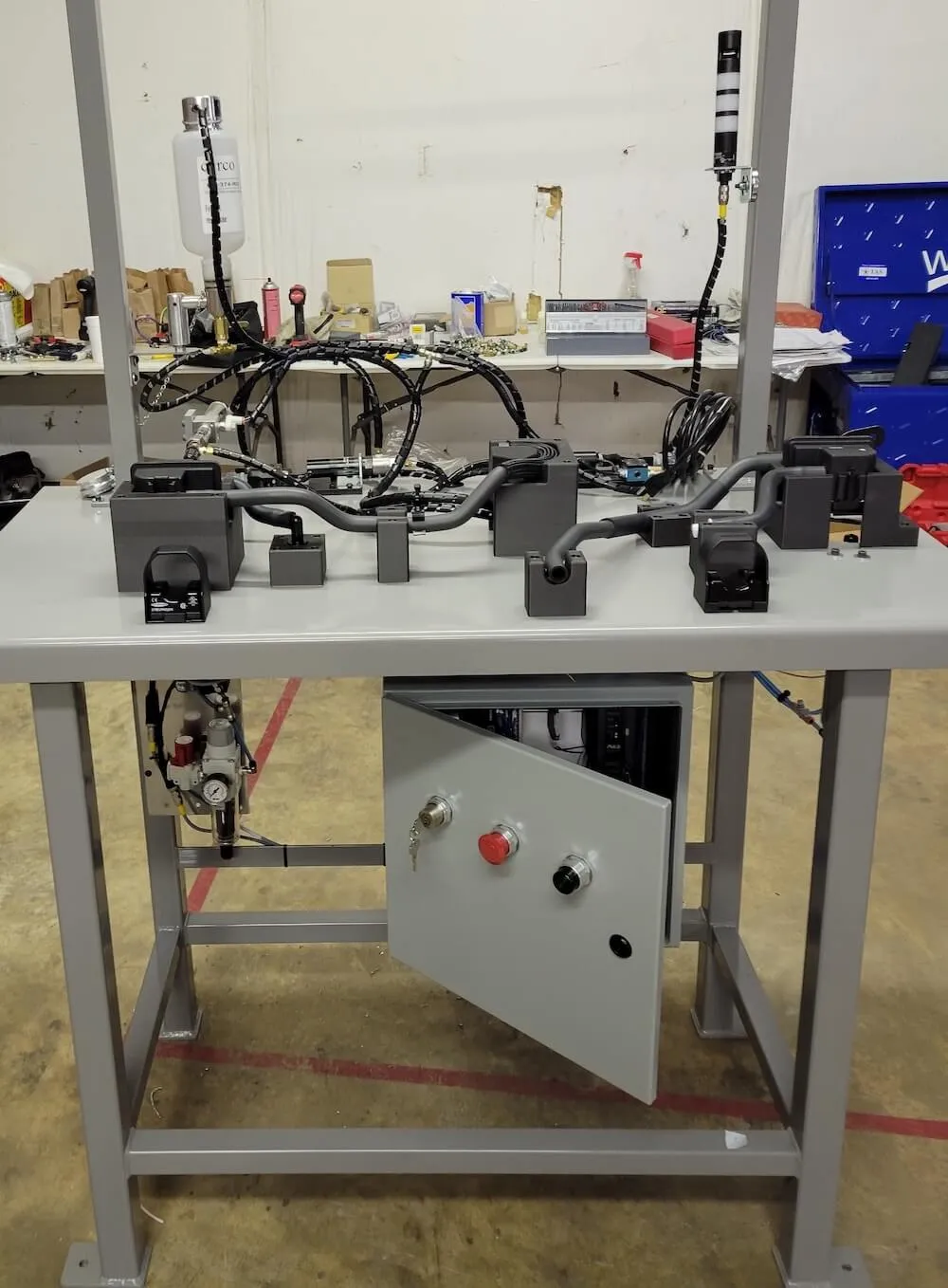

Some Recent Custom Design & Build Projects

Click on any image to enlarge